Discover rewarding casino experiences.

Please Don't Quote Me Although a Prince built that Castle, one didn’t need to be Royalty to Dine there. |

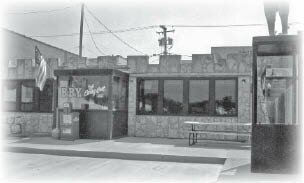

It was an Earl who built the Castles; not earl in the form of rank, but Earl the name, Earl Prince, who built Prince Castle ice cream businesses and really was the forerunner of fast food franchises to come. They were distinctive “ice cream castles,” as they were first called. Perhaps they were first in the food dispensing line to have an identity all their own, long before golden arches or a white bearded southern colonel emblazoned everywhere. The first Prince Castle was built in DeKalb in 1929 and by the mid-1930’s so many had been put up that like all facets of the business their construction had been efficiently planned out to be able to erect and dismantle them easily to move them to other sites ... Bolted panels were cover for concrete blocks with a veneer of native limestone as the facade ... The crenelated roof edging like the battlement of the real castle was simulated in the miniature. The one pictured here still is in use in Dixon as a chicken specialty cafe at the south end of Peoria Street bridge. The chicken on top beckons you. That first Castle in DeKalb had a woman for a manager, Anna Campbell, a feature of nearly all the Castles thereafter, not a common thing back then. This was long before the glass ceilings, women’s rights and being politically correct. Interiors of the Castles were as unique as the exterior, they too being designed by Earl and his staff, most of whom were boyhood friends of Prince. For years they worked together foreseeing and solving the direction of the chain. All display and storage cases were alike in those days so Earl and staff re-did the tops of the display cases, for instance, by making them all glass instead of solid material so the product could be more easily seen. Walls were ceramic tile, as well as floors. They were easily maintained and brightly clean to appeal to the customer. Each level of the business had the customer in mind by foreseeing quality control and shopping locally instead of just aiming for pure profit. At first only cones and pint packages were merchandise sold. Why only cones and/or pints? Ice cream was not just a family business, it had become a family inclination. Earl was born in Downers Grove in 1894, had graduated from the University of Wisconsin, Madison and became a surveyor for a Canadian railroad company. Meanwhile, his father, Earl H., had led a varied career and some adventures by going to the Gold Rush in Alaska with his brother, then buying a ranch in the Williston Basin in North Dakota. He sold that and came to a conventional little town in Illinois, Rushville, where he bought a business that included the Star Creamery, a wholesale ice cream manufacturer. Earl, Jr. joined him and they soon discovered that by selling directly to the consumer was much more pleasing and profitable and less complicated. Earl, Jr. had taken over the ice cream part of the business while his father had come to Dixon to buy the Dixon Distilled Water Ice Co. The two joined buildings together to share the refrigeration equipment. And though they were going to sell ice cream, Earl, Jr. as yet had no way to manufacture or distribute it. At first he bought it from another school days friend, Walter Fredenhagen, who made “Frozen Gold Ice Cream” at the Naperville Creamery. The two businesses connected in name only, Fredenhagen constructing several Prince Castles in the northern suburbs of Chicago, while Prince built throughout northern and northwest Illinois and Indiana. They shared in buying supplies, etc. and advertising arrangements, but otherwise did not share in the other’s business until Fredenhagen sold out to Borden’s. The same year as the DeKalb opening, 1929, Earl, Jr. bought “Peoples Ice and Coal” in Sterling, 2nd Street, and built headquarters of the Prince Castle business there plus manufacturing and packing for the product. Eventually there were two hundred fifty employees there with perhaps a thousand part-timers. In the beginning years of the operation the Castles were only open in the summer months, closed during the winter, when it was supposed ice cream wasn’t a wanted item. Prince and staff got to thinking about all the people put out of work by this arrangement and decided to try staying open year-round. What to sell? Chili and hamburgers, but only in winter months! Those square burgers became a sensation, yes, square like the square dips of ice cream were a trademark of the Castles ... Another detail worked over by staff. They had already redesigned the 2½-3 gallon bulk ice cream containers from round to square for more efficient loading and delivery and changing them from sturdy metal to heavy cardboard as soon as they were manufactured ... The weight was considerably less and they didn’t need to be returned to the creamery to be cleaned for reuse, just disposed of. The square scoops were more efficient by being thrust straight down, instead of turning the wrist with a round scoop ... It’s been suggested that onset of carpal tunnel of scoopers was reason to change but that’s not a written fact. Expansion at the Second Avenue site in Sterling was on-going as new ideas and new methods were in constant motion. The quality of ice cream remained excellent: 12% butterfat, 18% sugar, 14% milk solids. Air whipped into that mixture, called overrun, was 80% to 100% and MMMMMM, it was good. Four or five refrigerated trucks were loaded each night to set out early to the dozen, two dozen Castles around the area. They were home by nightfall. The hamburgers eventually on the year-round menu, were meaty; the Castles organization using the whole steer for the meat mixture from Swift and Co., Rochelle. Trading locally in the dairy department, Dean’s Milk was used, Pecatonica. Sam Dean himself often delivered the product back then. If the Prince Castle organization ever planned or knew they were becoming the prototype for many features and methods in the fast food business it doesn’t come out in material written about it. Their use of cardboard cups and plates, wooden spoons, disposables of all kinds, changed the industry in many ways but an addition besides hamburgers, chili, sodas and sundaes (they made all their own toppings, too) was the malted milk in 1936. No, they didn’t invent the malted milk but they did invent a malted milk MACHINE THAT CHANGED THAT PART OF THE ICE CREAM BUSINESS. Prince Castle’s malt was known far and wide as the “One-in-a Million,” thick and rich, they lived up to their name. And the machine that mixed it grew to more than a million when manufactured. It was called the Multi-Mixer and developed by Earl, Jr. and staff for reasons they best knew . . . To speed up making of malts for crowds of people. It was sold world-wide — another innovation from Prince Castle. And who would be your guess at who became the salesman for the Multi-Mixer? He became rich and famous in the business he later initiated—world-wide. Next Week!

|